By admin | March 19, 2021

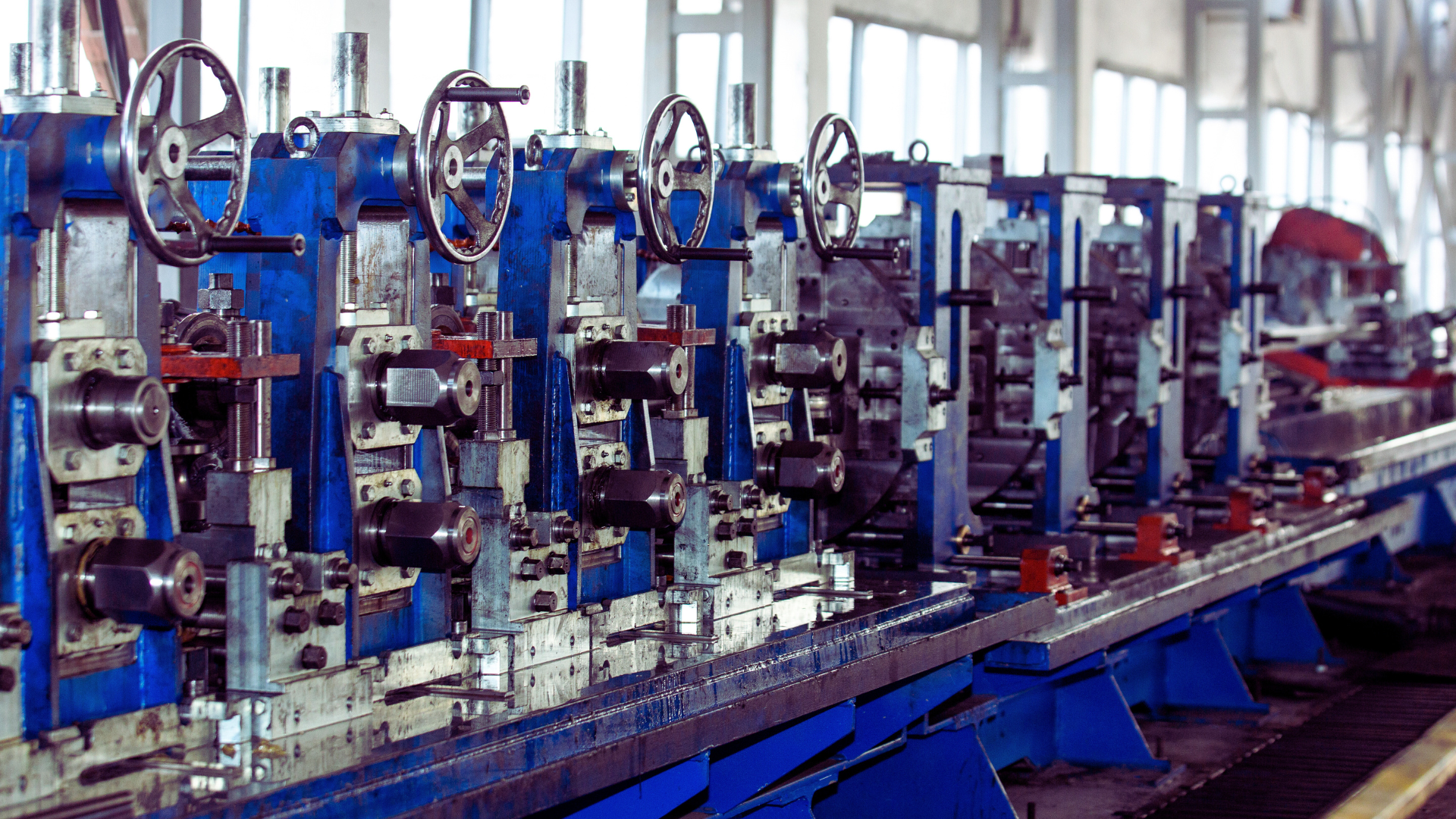

Milling is an important part of several types of manufacturing industries. Today, milling machines are used to make the process of milling much easier and faster. There are several types of milling machines available on the market. Most are multi-purpose machines which can take care of a variety of tasks.

If you’re looking to make custom parts for use in a variety of different types of applications, then you may consider purchasing a milling centre which will help you with the milling process. Milling centres are of primarily two types: vertical machining centres and horizontal machining centres.

Vertical machining centres (VMC) are one of the most common types of milling machines used in factories.

What is a VMC Machine?

VMC machines are cutting machines that are primarily used to remove aluminium, steel, or other hard metals. Using a VMC, you can shape a hard block of metal into any shape that you need. This process will give you a machined surface on your basic material.

In addition to cutting, VMCs can also be used to drill, carve, engrave, or chamfer the basic raw material. A VMC has a wide variety of applications and is found in factories around the world. Some of the industries that commonly use VMCs include the automotive industry, shipping industry, machine shops, and manufacturing industry.

They also have a relatively low cost compared to other alternatives, which increases their popularity.

How many axes does a machine have?

VMC machines commonly come in three-axis, four-axis, or five-axis configurations, determining the machine’s ability, accuracy, and repeatability to move along different axes. The more axes a machine has, the greater its versatility and capability for complex machining operations.

Types of VMC Machine

There are various types of VMC machines tailored to specific industry needs, such as fixed-column, moving-column, or gantry-type machines. Understanding these types is crucial when selecting a machine that best suits specific manufacturing requirements.

Vertical vs Horizontal Lathe Machines

While both vertical and horizontal lathe machines have their merits, VMC machines excel in offering versatility, precision, and ease of use. Vertical machining centres often prove more suitable for intricate and complex machining tasks.

Vertical Machining Centre (VMC) Features for Improving Productivity

VMC machines boast numerous features aimed at enhancing productivity, such as automatic tool changers, high-speed spindles, and advanced control systems. These features significantly contribute to increased efficiency and reduced production times.

How to Choose a VMC Machine?

VMC machines come in several variations. This is why it is important to know your own needs before investing in one. Here are some of the main characteristics that you will need to consider.

Accuracy

Each VMC machine has a limit to its precision. There are types of VMC machines that are highly accurate and precise, whereas others are much less so. The higher precision machines also cost a lot more. Hence, you need to consider your own accuracy needs and purchase a VMC machine accordingly.

Rotary Device

You do not need a rotary device for every type of machining job. The basic 3-axis VMC will allow 3-dimensional cutting on one side of the workpiece. For more sophisticated jobs, you may consider a 4- or 5-dimension machine.

Manufacturer

Choosing the manufacturer is just as important as choosing the machine. You need to look into whether a manufacturer has a reputation for quality machines and fast service. You also need to check whether they continue to service old models.

Every kind of VMC machine is available for sale in Kolhapur, Maharashtra, Chennai, and most parts of India.

What are the Differences between CNC and VMC?

There are two types of VMC machines. Those that have a CNC and those that do not.

A CNC is a Computer Numerical Control. The CNC allows you to control the VMC through a computer-based input system. In VMCs which do not have a CNC, you need to use templates or cams to control the machine.

It is advisable to purchase a VMC that has a CNC because it is much easier to control the operation of the VMC through a computer rather than manually controlling it.

Advantages of VMC Machining

The advantages of utilising VMC machines include superior accuracy and precision, versatility, rigidity, reduced setup times, increased automation, and the ability to handle complex geometries. These benefits contribute to enhanced overall manufacturing efficiency of this cutting tool.

Used VMC Machine or New VMC Machine

You have the option of purchasing a second VMC machine or a brand new VMC machine. You’ll find many used VMCs for sale in India. The choice between the two depends entirely on your requirements and your budget.

A second-hand VMC machine will have wear and tear on it that will reduce its overall life. A brand-new machine will have a longer life.

However, the VMC machine price can be a lot higher for new machines compared to used machines. It is quite easy to buy and sell VMC because there is a large market for such machines in India.

Final Thoughts

Investing in a Vertical Machining Center is a significant decision for any manufacturing business. Understanding the nuances of VMC machines and their capabilities and aligning them with specific production requirements are vital steps towards achieving operational excellence.

FAQs:

What is the principle of VMC?

The principle underlying VMC (Vertical Machining Centers) is the vertical orientation of the spindle speed, allowing for precise and versatile machining operations. These machines use vertically aligned tools to perform various tasks like milling, drilling, and shaping materials, enabling high-precision manufacturing processes.

Which motor is used in the VMC machine?

The motor commonly used in VMC (Vertical Machining Centers) is the spindle motor. This motor drives the spindle, enabling the machine to perform cutting, drilling, and milling operations with precision and efficiency.