Protecting their assets is one of the top priorities of any small business to control costs and maintain their productivity levels. For a small manufacturing or production business, industrial equipment and machinery are the key assets to protect. These machines are a significant financial commitment on a business’ part – either new or pre-owned – and are crucial to keeping the operations running smoothly and keeping up productivity. And sure, you can get a machinery loan for a small manufacturing business if you need to upgrade your equipment, but this can put a significant dent in your working capital and cash flow. Therefore, your industrial equipment and machinery are assets you must safeguard. And you cannot afford to overlook the maintenance of your machinery if you want to keep it in good operating order.

So, here are some simple tips and tricks you can use to properly maintain your machines:

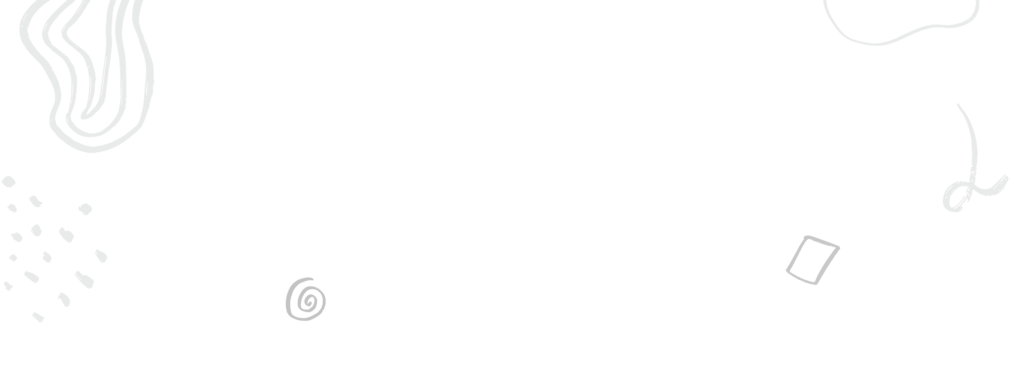

Understand Your Equipment

Learning about and understanding your equipment is the first and most significant step in maintaining your machinery. In addition to understanding how to correctly operate the machine, learning about the industrial equipment you use daily can also help you identify the optimal settings for your needs, perform regular checks, prepare a maintenance schedule and appraise any situations where repairs are necessary. The user manual and other documents that come with the device are your best sources of information to learn about your machinery.

Schedule Regular Maintenance

A regular maintenance schedule is your best friend when it comes to maintaining your industrial equipment and keeping it in optimal working condition. Regular servicing and maintenance let you spot and fix many small problems before they become apparent – much more expensive to repair. And having in-house service experts to regularly check and maintain your machinery is a bonus as they can check all your equipment and see if any additional servicing is necessary.

Leverage Service Contracts

Hiring and retaining in-house service experts may be expensive for your small business. In such cases, you can leverage machinery service contracts to access service and repair experts that can come to your business regularly and perform regular servicing or necessary repairs. Without a service contract or a good relationship with your service firm, you may struggle to access repair technicians on schedule or need to pay additional costs with last-minute requests to third-party firms.

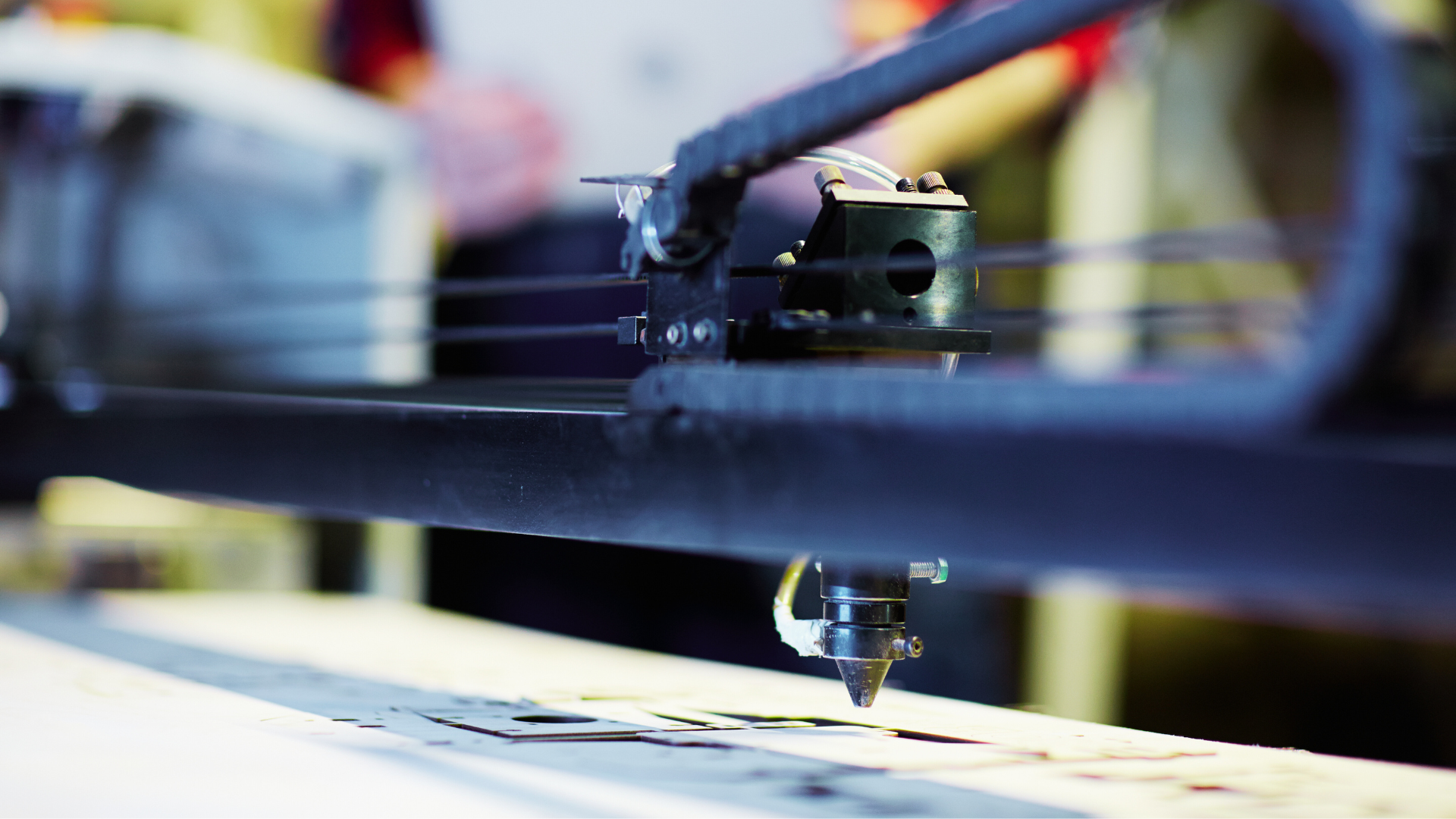

Regularly Replace Worn-Down Parts

Small parts in your machines, like seals, bearings, pulleys or gaskets, may get worn down over time. Parts like belts can elongate, or sprockets can experience breakage. It is necessary to replace worn-down or broken parts or perform torque checks on belts regularly to keep them in optimal working conditions.

Look for the Best Deals When Purchasing New Machinery

Purchasing industrial equipment, new or pre-owned, is a huge financial commitment, so ensuring the machinery will perform optimally long enough to give you a good return on investment is crucial. Be sure to look for the best deal, negotiate the terms and conditions of your warranty and keep those in mind when your machine faces a problem. Make sure you understand what the warranty covers and what repairs the manufacturer will cover to save unnecessary repair costs during the warranty period.

Train Your Employees

Overutilisation of machinery or neglecting safe operating procedures can increase the likelihood of mechanical failure or machine breakdown. And your machines can fail even with diligent preventative maintenance if the employees do not follow operational recommendations. Training your employees on these procedures can ensure they are not over utilising or neglecting your equipment. Additionally, if the employees know about preventing wear and tear or performing minor repairs, you can ensure the longevity of your industrial equipment.

With these simple tips and tricks in mind, you can keep your industrial equipment functioning in good order and save on unnecessary repair or new equipment purchase costs.

Take Away

Industrial equipment is one of the biggest assets for small manufacturing and production businesses, and maintaining them well is a great way to avoid the huge financial commitment of securing a machinery loan for your small business and purchasing new machinery. Following some simple tips and tricks, like learning about your machinery, regular servicing and maintenance, timely replacement of worn-down parts, and employee training, can help you maintain your industrial equipment in good operating order.

And if you are ready for the financial commitment of purchasing new equipment for your small manufacturing business, Electronica Finance Ltd (EFL) machine loans can offer you quick and easy cash with no additional collateral. With the option to get a machine loan of up to INR 3 crore within seven working days and a loan repayment period of 5 years, you can reduce the strain on your working capital while ensuring seamless operations and productivity. EFL’s MSME machine loans are a great way to upgrade your machinery – without affecting your cash flow – and grow your business.