A machining centre is a critical component of any modern machine shop, and choosing between a Vertical Machining Center (VMC) and a Horizontal Machining Center (HMC) can significantly impact productivity, profitability, and machining efficiency. Many manufacturers have long relied on vertical machining centres, but the benefits of horizontal machining centres are becoming increasingly evident.

This article explores the considerations when expanding or upgrading your CNC machining centre.

Why Adapting to Change in Manufacturing Matters

As technology evolves, so do machining techniques and strategies. Manufacturers must carefully consider the advantages of new machinery to maintain a competitive edge. The ability to compete in today’s market depends on investing in efficient machine tools that optimise uptime, throughput, and precision. Whether you are expanding or upgrading your CNC capabilities, considering the advantages and disadvantages when expanding is crucial to making an informed decision.

The Debate: Vertical Machining Centers (VMC) vs. Horizontal Machining Centers (HMC)

We’re building a case for how an HMC is the most cost-efficient investment for your machining needs. However, we will go through the features of both VMC and HMC, and suggest with evidence which one suits well for which needs.

Vertical Machining Centers (VMC)

A quality VMC may be the machine of choice for many businesses due to its affordability and ease of use. Vertical CNC machining is a cost-efficient solution for manufacturers producing simple workpieces that require minimal part handling. However, VMCs often have longer cycle times and require more human intervention, which increases labour costs and potential human error.

Horizontal Machining Centers (HMC)

HMCs, on the other hand, provide significant advantages in complex machining applications. One HMC instead of multiple VMCs means fewer fixtures, reduced setup times, and improved throughput. Horizontal machines are designed with a horizontal spindle, which allows for greater access to the workpiece, making them ideal for machining operations that require precision and accuracy.

The ability to perform multiple machining techniques in a single operation enhances productivity and surface finishes, making HMCs the preferred choice for high-quality machined parts.

What Are the Benefits of an HMC for Your Business?

1. Increased Productivity and Efficiency

One of the key benefits of horizontal machining centres is their ability to handle multiple workpieces simultaneously. The rotating cutting tools in an HMC allow for fixture-to-fixture transitions with minimal downtime, resulting in higher uptime and improved machining technology. Instead of multiple VMCs means fewer fixtures, which streamlines the milling process and enhances throughput.

2. Better Precision and Accuracy

HMCs offer superior precision and accuracy, reducing human error and ensuring consistent material removal from a workpiece. This makes them an excellent choice for industries requiring high-quality machined parts. The horizontal orientation of an HMC provides better access to the workpiece, making it easier to produce complex parts with intricate designs.

3. Cost-Efficient Solution with Reduced Setup Times

HMCs can replace three VMCs by performing multiple machining operations in a single setup. This eliminates the need for multiple fixtures and reduces setup times, making HMCs a cost-efficient solution for businesses looking to optimise their machining needs. The ability to machine a six-sided part with only three touches by the operator significantly improves efficiency and reduces part handling.

4. Improved Tool Life and Surface Finishes

Horizontal and vertical milling processes differ in their impact on tool life and surface finishes. In an HMC, chips fall away from the cutting tool and workpiece, preventing recutting and extending tool life. This results in better surface finishes and higher-quality products. The horizontal milling process also enhances the ability to remove material from a workpiece more efficiently.

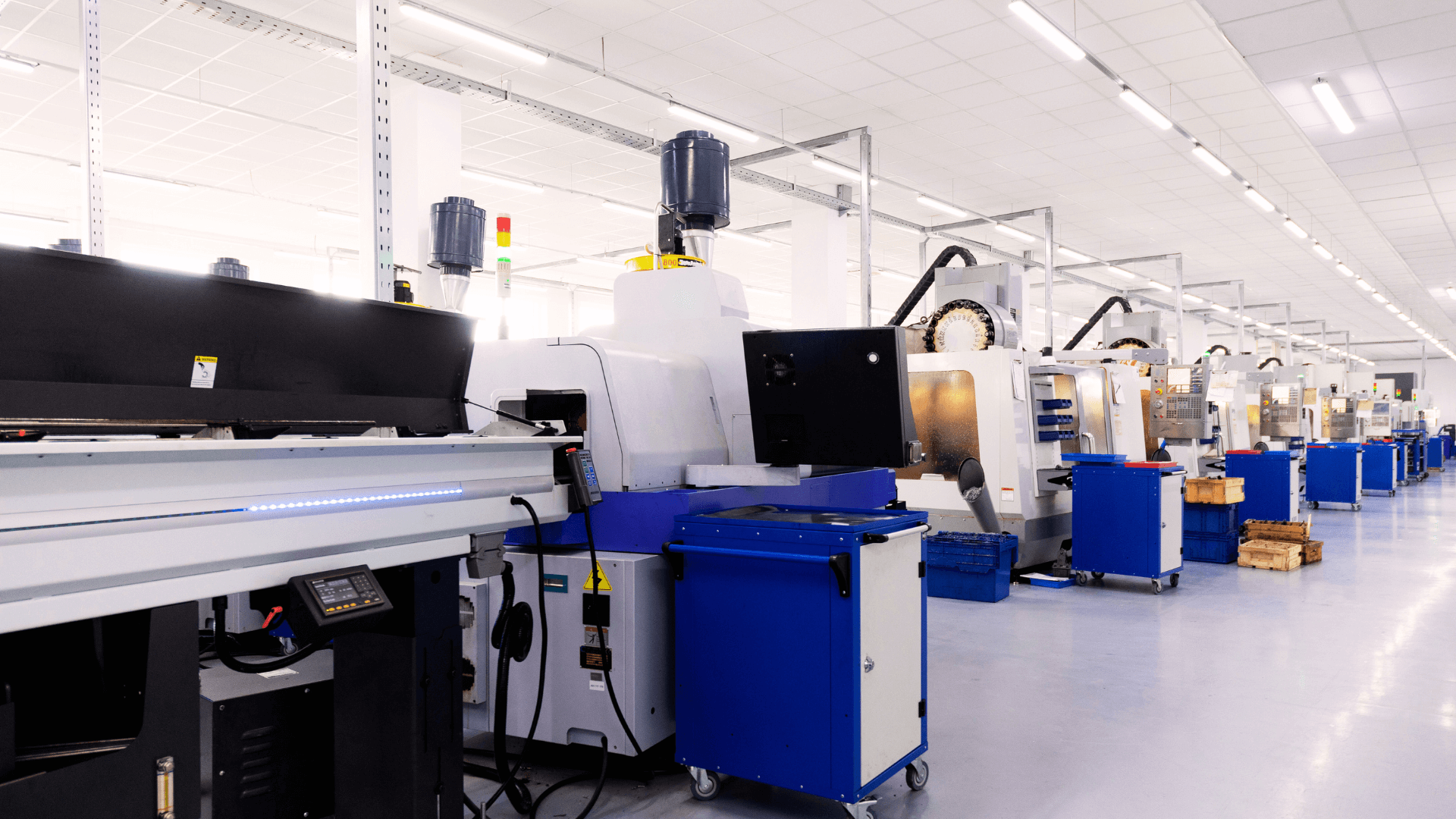

5. Optimal Use of Floor Space

Manufacturers must consider the optimal use of floor space when choosing between an HMC and a VMC. Horizontal machines typically require less floor space compared to multiple VMCs, making them ideal for facilities with limited room. Their efficient layout improves workflow and ensures that machining centres offer the best possible use of available space.

Conclusion

Choosing the right machining centre for your business requires careful analysis of machining technology, machining operations, and part handling needs. While VMCs have their place in the industry, the benefits of horizontal machining centres outweigh the disadvantages when expanding or upgrading.

HMCs provide increased productivity, reduced labour costs, and superior precision, making them the preferred choice for complex machining applications. That’s why it’s important to carefully consider the advantages and disadvantages before investing in a CNC machine.

Look for an easy, reliable, and safe machine loan option that will help your business scale up.

—

FAQs

What is a horizontal machining centre (HMC)?

A horizontal machining centre (HMC) is a CNC machine designed with a horizontally positioned spindle. This setup is well-suited for high-volume production, heavy-duty cutting, and machining multiple surfaces efficiently.

How is an HMC different from a vertical machining centre (VMC)?

The key distinction between the two lies in spindle orientation: an HMC features a horizontal spindle, whereas a VMC has a vertical spindle. HMCs excel in large-scale production, accommodating bigger workpieces and ensuring superior chip evacuation.

Why should I consider investing in a horizontal machining centre?

Choosing an HMC comes with multiple advantages, such as quicker production cycles, enhanced chip removal, improved surface quality, and the capability to machine multiple sides of a part in a single setup, boosting overall efficiency.

Which industries benefit the most from horizontal machining centres?

HMCs are widely utilised in sectors such as aerospace, automotive, heavy machinery manufacturing, and medical device production, where precision, efficiency, and the ability to handle complex or large parts are essential.

How does an HMC enhance productivity?

HMCs streamline machining by enabling multi-side processing within a single fixture setup, reducing setup time. They also offer higher spindle speeds, quicker tool changes, and superior chip management, leading to shorter cycle times and greater production output.