Welcome to our guide on launching a profitable job shop by financing your CNC machining centre for home workshops. In this post, we’ll explore the essential steps and considerations for starting a financially viable job shop with a focus on securing financing for your CNC machining business tailored for home-based operations. Let’s dive in!

Understanding the Landscape of Job Shops:

Before delving into the specifics of financing your CNC machining centre for home workshops, let’s first understand the concept of a job shop and its significance in the manufacturing industry. A job shop is a type of manufacturing facility that produces custom-made products in small batches, catering to diverse customer demands. With the emergence of home workshops, the accessibility of CNC machine shops has expanded, allowing individuals to pursue entrepreneurial endeavours from the comfort of their homes. Starting a job shop can be a good business opportunity for those interested in entrepreneurship, especially with the availability of new CNC technology.

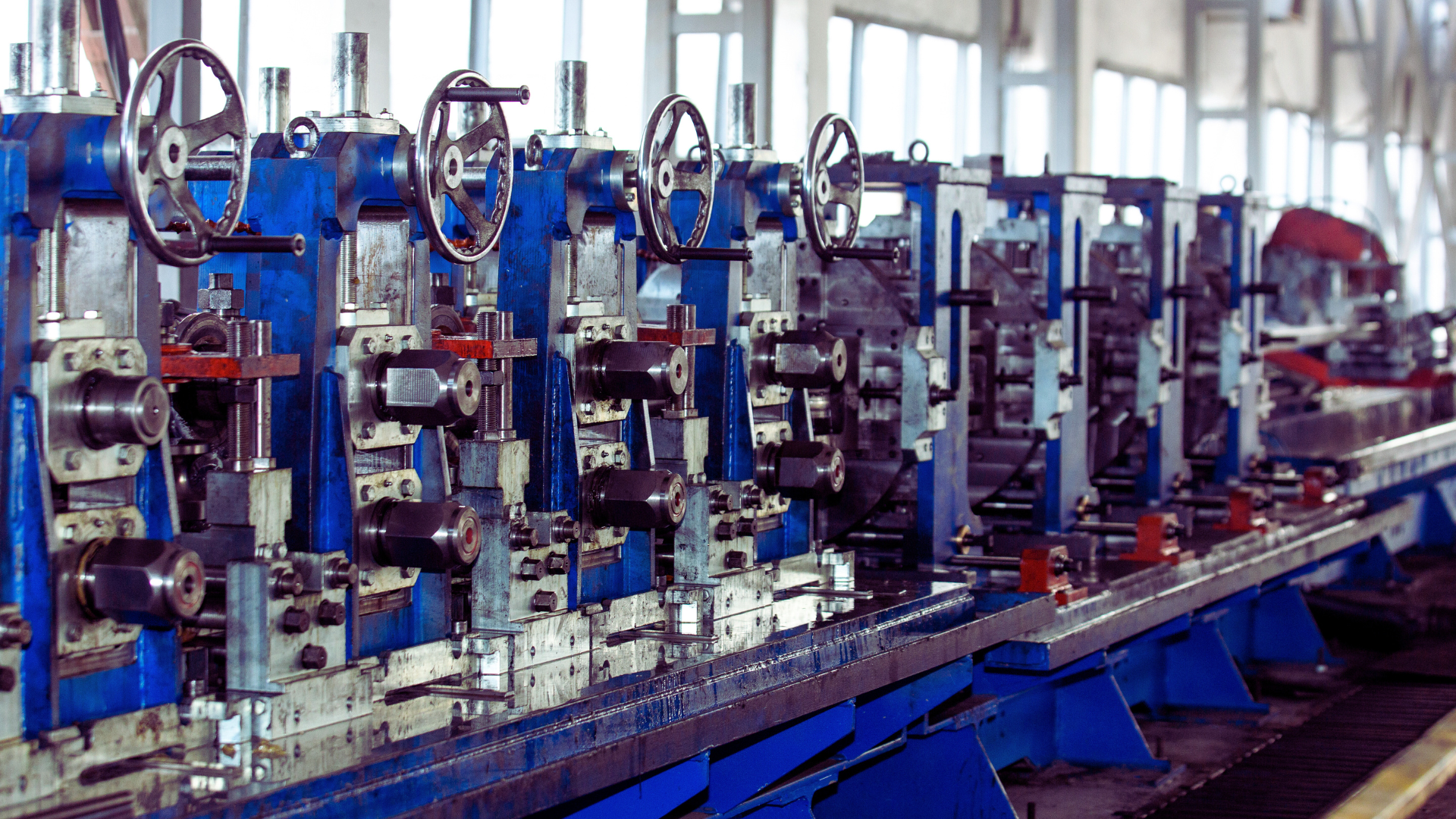

The Role of CNC Machining Centres for Home Workshops:

Central to the success of any home workshop job shop is the CNC machining centre. CNC (Computer Numerical Control) machining technology allows for precise and efficient manufacturing processes, enabling home workshop owners to deliver high-quality products with minimal space requirements. Investing in a CNC machining centre tailored for home workshops is crucial for enhancing productivity, accuracy, and competitiveness in the market.

Financial Considerations for Starting a Job Shop:

Launching a job shop in a home workshop requires careful financial planning and consideration of the various costs involved. These costs may include equipment purchases, facility setup, raw materials, marketing, and administrative expenses. Securing financing for machinery purchases, particularly for the CNC machining centre for home workshops, is a critical aspect of starting a job shop. Exploring different financing options and assessing their terms and conditions is essential for making informed decisions that align with the needs of home-based operations.

Assessing Viability and Feasibility:

Before committing to starting a job shop in a home workshop, it’s essential to assess the viability of home-based operations. Evaluating the potential profitability of the business and considering factors such as market demand, competition, pricing strategies, and operational efficiency is crucial. Additionally, determining the optimal setup and layout for your home workshop, accounting for space constraints and safety considerations, is essential for ensuring feasibility and success.

Understanding Loan Options for CNC Machining Business Centers for Home Workshops:

When it comes to financing your CNC machining centre for a home workshop, there are various loan options available. These may include traditional bank loans, equipment financing specifically tailored for home-based businesses, loans from NBFCs and alternative lending solutions. Understanding the advantages and disadvantages of each loan option, as well as their eligibility criteria and repayment terms, is essential for making the right choice that meets the unique needs of home workshop operations.

Ensuring Financial Stability:

Proper financial planning is essential for ensuring the long-term stability and success of your job shop in a home workshop setting. Mitigating risks associated with loan repayment, maintaining healthy cash flow, and implementing effective cost management strategies are key considerations. Developing a comprehensive business plan that outlines your financial projections, marketing strategies, operational plans, and growth initiatives tailored for home-based operations is crucial for guiding your business toward profitability and sustainability.

Conclusion

In conclusion, starting your own CNC machining centre for home workshops requires careful planning, strategic decision-making, and a commitment to excellence within the unique context of home-based operations. By understanding the landscape of job shops, assessing viability and feasibility for home workshops, exploring loan options tailored for home-based businesses, such as machine loans, and ensuring financial stability through proper planning and execution, you can set your home workshop job shop on the path to success. Remember, with dedication and perseverance, home-based entrepreneurs can achieve their goals and contribute to the manufacturing industry from the comfort of their homes.

FAQs:

Can you make money with a CNC at home?

Making money with a CNC machine at home is entirely possible. With the right skills, equipment, and market opportunities, individuals can create and sell a wide range of products, prototypes, or custom parts using their CNC machines. By adopting a strategic marketing approach, they can effectively reach potential clients and maximise their business opportunities. Many hobbyists, artisans, and small businesses generate income by offering CNC machining services, creating unique crafts, producing custom furniture, or fulfilling orders for specialised components. It’s essential to consider factors such as market demand, pricing strategies, and operational costs to maximise profitability. Ultimately, success with a CNC machine at home depends on creativity, dedication, and entrepreneurial spirit.

Is owning a CNC machine profitable?

Owning a CNC machine can be profitable for individuals and businesses alike. With the ability to automate manufacturing processes, CNC machines offer efficiency, precision, and versatility, enabling owners to produce a wide range of products with high quality and consistency. From creating custom parts and prototypes to fulfilling orders for niche markets, owning a CNC machine opens up various opportunities for generating revenue. However, profitability depends on factors such as market demand, operational efficiency, pricing strategies, and cost management. By leveraging the capabilities of their CNC machine effectively and exploring diverse market opportunities, owners can maximise profitability and achieve success in their endeavours.

How do you start a CNC business in India?

Starting a CNC business in India can be an exciting venture with promising opportunities. Here’s a simplified guide to get you started:

Research and Planning: Begin by researching the CNC market in India. Identify potential niches, assess market demand, and analyse competitors. Develop a business plan outlining your goals, target market, services offered, and financial projections.

Obtain Necessary Skills and Training: Acquire the necessary skills and expertise in CNC machining. Consider enrolling in training programs, courses, or workshops to enhance your knowledge and proficiency in operating CNC machines effectively.

Secure Funding: Determine your startup capital requirements and explore funding options. This could include personal savings, loans from financial institutions, or investments from partners or investors.

Set Up Your Workshop: Find a suitable location for your CNC workshop with adequate space for machine installation, material storage, and workspace. Ensure compliance with local regulations and zoning laws.

Purchase Equipment: Invest in high-quality CNC machines and equipment suitable for your business needs and budget. Consider factors such as machine size, capabilities, and compatibility with the types of projects you plan to undertake.

Obtain Necessary Licenses and Permits: Register your CNC business and obtain the necessary licenses and permits required to operate legally in India. This may include business registration, tax registration, and environmental clearances, depending on your location and business activities.

Develop Marketing Strategies: Create a marketing plan to promote your CNC business and attract customers. Utilise online platforms, such as websites and social media, to showcase your services, portfolio, and capabilities. Network with local businesses and industry professionals to build relationships and generate leads.

Provide Excellent Service: Focus on delivering high-quality products, timely delivery, and exceptional customer service to build a reputation for reliability and professionalism. Satisfied customers are likely to become repeat clients and refer others to your business.

Stay Updated and Evolve: Keep abreast of industry trends, technological advancements, and market developments. Continuously improve your skills, processes, and offerings to stay competitive and meet the evolving needs of your customers.

Starting a CNC business in India requires careful planning, dedication, and perseverance. By following these steps and adapting to the dynamic business environment, you can build a successful and profitable CNC business in India.

How can my business generate revenue?

Your business has the potential to generate revenue by leveraging its ability to make products. By utilising CNC machining technology, you can create a wide variety of products that cater to different market demands. Additionally, remaining open to new opportunities and exploring various markets can expand your customer base. With CNC technology becoming more accessible, many shops are embracing this innovation to enhance their manufacturing capabilities and increase their revenue streams. By tapping into this trend and offering quality products, your business can thrive in today’s competitive market landscape.